A new test to measure impact protection was added to the EN388 standard. The method for testing is:

The Abrasion Test is designed to give an indication of the durability of the gloves. The performance levels are still the same but the sandpaper used to perform the test has been changed from 100 grit to a finer 180 grit material.

| Test | Level 1 | Level 2 | Level 3 | Level 4 |

| Abrasion Resistance (number of cycles) | 100 | 500 | 2,000 | 8,000 |

The method for testing the cut resistance of gloves has been typically carried out using a circular blade which moves back and forth across the surface of the gloves. This test is commonly referred to as the Coup Test. The revisions to the Coup Test are:

| Test | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

| Circular blade cut resistance (number of cycles) | 1.2 | 2.5 | 5 | 10 | 20 |

The Straight Blade test can be used in lieu of the Coup Test. It should also be used if the Coup Test reaches 60 cycles or if the cutting factor is greater than 3.

| TDM Test Method: EN ISO 13997 | Level A | Level B | Level C | Level D | Level E | Level F |

| Straight blade cut resistance (N) | 2 | 5 | 10 | 15 | 22 | 30 |

The EN 407 heat and flame pictogram is accompanied by a 6 digit number. This 6 digit number identifies the performance levels (1-4) which a glove can achieve for each of the tests within the standard. The higher the performance level, the greater the protection of the glove against a range of thermal risks as described below:

A - Resistance To Flammability

Measures how likely a glove is to catch fire after a flame is applied.

B - Resistance To Contact Heat

Measures the ability of a glove to resist heat when placed in direct contact with a heated object or hot surface.

C - Resistance To Convective Heat

Measures the ability of a glove to resist heat from a flame source.

D - Resistance To Radiant Heat

Measures the ability of a glove to resist heat from a radiant heat source.

E - Resistance To Small Splashes of Molten Metal

Measures the specific amount of molten droplets (from a melted metal rod), required to raise the inside temperature of a glove by 40°C.

F - Resistance To Large Splashes of Molten Metal

Measures the amount of molten iron (in grams) required to cause damage to "simulated skin" placed inside the glove.

EN 511:2006 is the European Standard specifying the requirements and test methods for gloves which protect against conductive cold down to -50 degrees Celcius. This cold can be linked to climate conditions or an industrial activity.

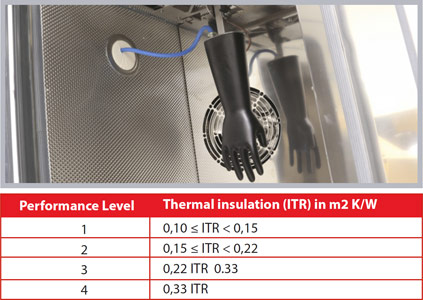

A glove is placed on a hand model which is heated between 30-35 degrees Celsius in a test chamber. The amount of energy required to maintain this heat determines the performance level of the glove. This is calculated by applying a specific formula known as the resultant thermal insulation formula or (ITR) as outlined in the table to the left. There are 4 performance levels overall. The higher the performance level the greater the insulation properties of the glove.

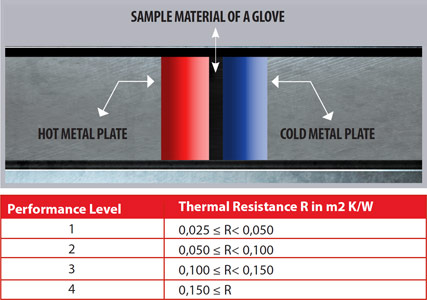

A sample material of a glove is placed into a test chamber between 2 metal plates, one heated and one cold. A Thermal Resistance (R) formula measures the temperature drop across the test sample which is then compared to that of a control sample (non thermal material) in order to calculate its thermal resistance. There are 4 levels ranging from 1-4, the higher the thermal resistance the greater the insulating capacity of the glove to insulate against cold.

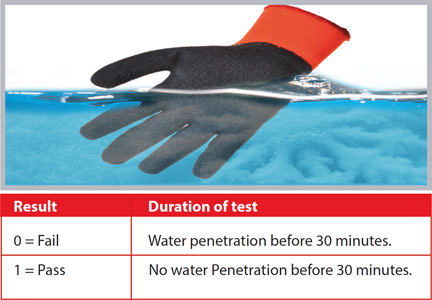

The Water Penetration test or Water Impermeability test is a straight forward test based on a pass/fail basis. The glove sample is submerged into water, if after 30 minutes no water has managed to penetrate the glove then it is deemed to have passed the test, otherwise it is classed as a fail.

The results are indicated by either 0 or 1.

Handle welding and metal tasks even in cold conditions with ease and safety using the Portwest Reinforced Winter Welding Gauntlet in Brown. Building upon the foundation of the popular A530 gauntlet, the A531 is specially designed to deliver exceptional performance in chilly environments, thanks to its rich feature set that combines warmth, durability, and protection in one gauntlet.

Key Features:

Compliance with Industry Standards:

The Portwest Reinforced Winter Welding Gauntlet not only provides a warm haven for your hands in cold conditions but stands as a fortress against burns and other hazards common in welding environments. Whether you're working in welding or metal handling, this gauntlet, marked with CE and UKCA, promises both comfort and safety. Reach for the best with the A531 Reinforced Winter Welding Gauntlet.

Please see our PPE disclaimer at the bottom of the page.

Specifications are subject to change - See Terms & Conditions for more info

Portwest has been independently rated by Ecovadis for its environmental, social, and ethical performance and achieved a silver rating, meaning they are in the top 25% of globally rated companies.

The pillars taken into consideration include the environment, labour practices and human rights, ethics, and sustainable procurement.

This product conforms with essential health and safety requirements as set out in European Directives.

This symbol indicates UKCA marking in progress at time of print. All products placed on the UK market from January 2023 must be UKCA marked.