EN353-2 relates to systems made up of a line intended to be fixed (either temporarily or permanently) to a structure at the top only, on which a travelling device is attached. The user connects to this travelling device when climbing or descending – in the case of a fall, the travelling device should grip the line and arrest the fall.

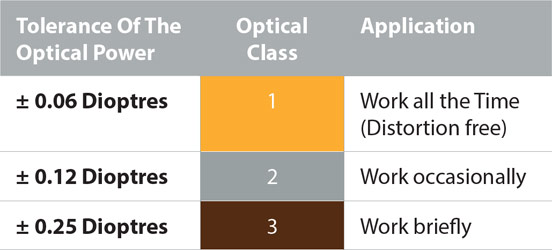

Tests include: transmission and diffusion of light, refractive properties, resistance to aging (stability to heat and resistance to UV), corrosion and ignition. Results of the testing define the Optical Class of the eye protector: which falls into 1 of 3 categories, where 1 is the highest and 3 is the lowest as indicated in the table. These categories define the quality of the lens in terms of how much or how little distortion is experienced by the wearer.

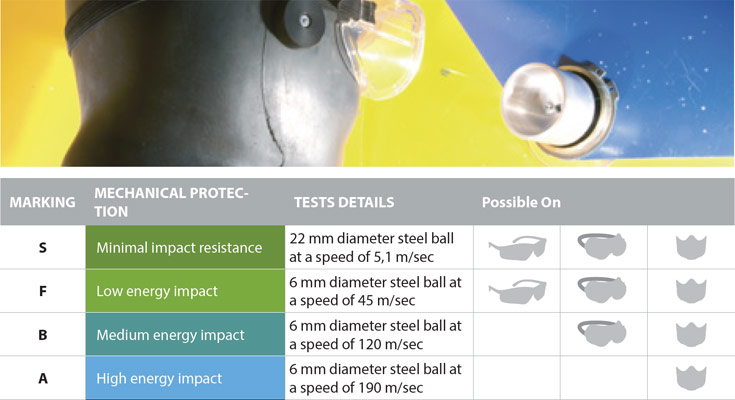

This test (applicable to both lens and frame) determines the impact resistance of the eye protector (spectacles, goggles or visors) to withstand flying objects without cracking or shattering. The test is performed with steel balls of different diameters and weights which are used to strike the lens and frame at different speeds as indicated in the table. This results in 4 levels of mechanical protection denoted by the markings; 'S' 'F', 'B' or 'A' on the eye protector where 'S' is the lowest grade, offering the least amount of protection and 'A' is the highest grade offering maximum protection under the standard.

Note: spectacles can only get a S or F marking, goggles can have a S, F or B, whereas grade A is applicable to visors only.

EN 166 also describes other optional tests which must be applied should the manufacturer wish to make additional claims regarding protection. For example, the Impact Resistance Against High Speed Spectacles At Extreme Temperature is conducted on spectacles/goggles and visors conditioned at extreme temperatures from -5°C / +55°C, resulting in similar markings as the above table, with a T denoting temperature: FT / BT / AT. Note: This does not apply to the S marking category.

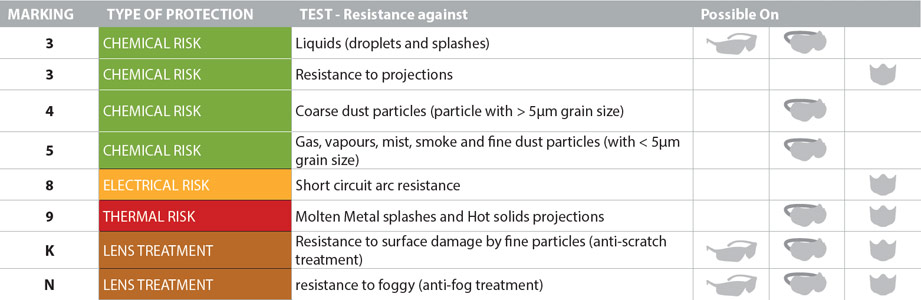

See the table to the left to see other optional requirements and their corresponding markings for EN 166.

This is the European standard for PPE for eye and face protection during welding and allied processes.

This standard specifies protection including ergonomic aspects against risks or hazards of radiative, flammable, mechanical, or and electrical nature. Welding PPE include spectacles, goggles, and face shields (manual face shields and head-gear face shields).

1. Principles of design:

The standard defines the minimum size of the visual field to allow the user to work safely but also to have a good field of vision during welding activities. Field of vision size is different for spectacles, goggles and face shields.

It also defines the characteristics of the materials used for this PPE, which must be opaque in all internal parts, to avoid reflecting light during welding processes.

2. Impact resistance, which can be:

3. Protection against molten metal splashes and hot solids projections:

This is an optional test for welding goggles and face shields (but not on spectacles) - when a PPE item passes this optional test it is marked with a corresponding marking "9".

Presenting the Portwest Gas Welding Goggle in Bottle Green – a state-of-the-art safety solution for welding aficionados. When working with oxyacetylene for gas cutting or welding, this goggle offers paramount protection complemented by unmatched comfort. With its shade factor 5, it’s an indispensable tool for all your welding needs.

Key Features:

The Portwest Gas Welding Goggle in Bottle Green is more than just a safety accessory – it's a testament to Portwest's commitment to delivering top-tier safety combined with ergonomic design. Elevate your welding experience with a goggle that’s built to last and designed to protect.

Please see our PPE disclaimer at the bottom of the page.

Specifications are subject to change - See Terms & Conditions for more info

Portwest has been independently rated by Ecovadis for its environmental, social, and ethical performance and achieved a silver rating, meaning they are in the top 25% of globally rated companies.

The pillars taken into consideration include the environment, labour practices and human rights, ethics, and sustainable procurement.

This product conforms with essential health and safety requirements as set out in European Directives.

Features a surface coating intended to mitigate scratch effects on the lens.

Features a surface treatment which helps reducing fogging effects on the lens.

This product has been individually packed for vending machines.