In order to comply with EN ISO 11611 all external pockets must be flapped, except for side pockets below the waist which do not extend more than ten degrees forward of the seam.

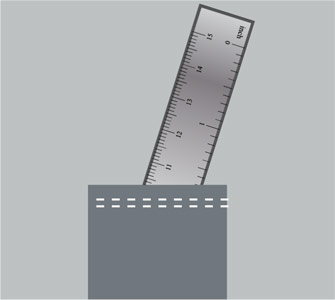

A single rule pocket with an opening not greater than 75mm is permitted behind the side seam on one or both legs.

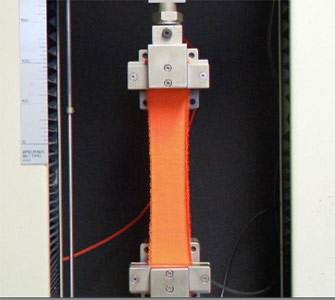

To meet EN ISO 11611 tensile strength must be at least 400N and tear strength must be at least 15N for class 1 and 20N for class 2.

For example:

Portwest's winning FR50 style has a tensile strength value of at least 500N and tear strength of at least 25N after 50 washes.

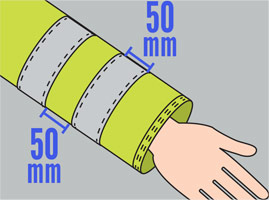

Reflective tape must be at least 50mm wide. Bands of reflective tape must be positioned at least 50mm apart.

Reflective tape must be positioned 50mm or more from the end of sleeve or leg.

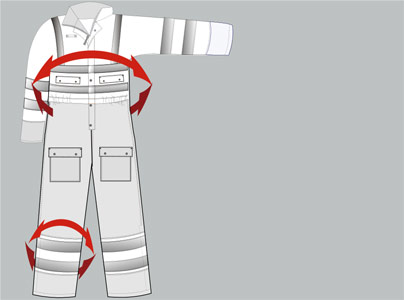

Reflective tape must encircle torso and/or limbs to be included in the calculation of the necessary square area of reflective tape. A gap (for fastening system or seam) in the band of reflective tape must be 50mm or less. The total amount of such gaps in every band must not exceed 100mm around the torso and 50mm around the sleeves and legs.

Highest level of protection - required for any persons working on or near motorways, dual-carriage ways or airports. Must incorporate a minimum of 0.80m2 of background material and 0.20m2 of retroreflective materials. (4 metres of 5cm wide reflective tape)

Required for any persons working on or near A and B class roads, also for delivery drivers. Must incorporate a minimum of 0.50m2 of background material and 0.13m2 of retro-reflective material. (2.60 metres of 5cm wide reflective tape)

Minimum level of protection required for any persons working on a private road or to be used in conjunction with a higher classed garment. Must incorporate a minimum of 0.14m2 of background material and 0.10m2 of retroreflective material. (2 metres of 5cm wide reflective tape)

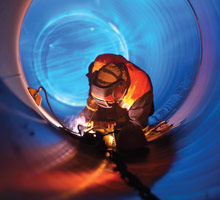

This international standard specifies minimum basic safety requirements and test methods for protective clothing for use in welding and allied processes (excluding hand protection). There are two classes with specific performance requirements.

Class 1 is protection against less hazardous welding techniques and situations, causing lower levels of spatter and radiant heat.

Class 2 is protection against more hazardous welding techniques and situations, causing higher levels of spatter and radiant heat.

The EN ISO 11611: standard has the following parameters:

For chemical protective clothing offering limited protective performance against liquid chemicals (Type 6 and Type PB [6] equipment). This standard specifies the minimum requirements for limited use and re-useable limited performance chemical protective clothing.

Limited performance chemical protective clothing is intended for use in cases of a potential exposure to a light spray, liquid aerosols or low pressure, low volume splashes, against which a complete liquid permeation barrier (at a molecular level) is not required.

Type 6 Chemical Protective suits must cover and protect at least the trunk and the limbs.

Example: One piece coveralls or two piece suits (with or without hood), boot-socks, or boot covers.

Type PB [6] Partial body protection covers and protects only specific parts of the body.

Example: coats, aprons, sleeves.

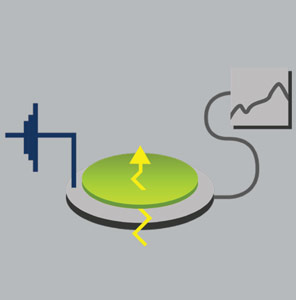

This European standard is part of a series of standards for test methods and requirements for electrostatic properties of protective clothing.

The standard specifies material and design requirements for garments used as part of a total earthed system, to avoid incendiary discharges.

The requirements may not be sufficient in oxygen enriched flammable atmospheres.

This European Standard is not applicable for specifying protection against main voltages.

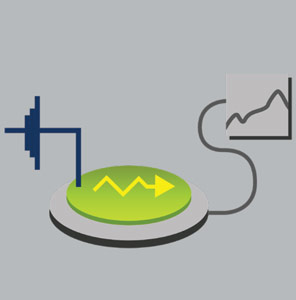

Test method for measurement of surface resistivity. Surface resistance measures the conductivity between two points on the surface of a fabric. The lower the resistance the higher the conductivity, resulting in charge going to earth.

Test method for measurement of the electrical resistance through a material (vertical resistance). This is the level of conductivity when measured through the depth of a fabric.

Test methods for measurement of charge decay. Charge decay measures how long it takes for an electric current to dissipate. The quicker it dissipates the higher the anti-static properties of the garment.

Please note the EN 1149-4 Garment Test is under development.

EN 1149-5 specifies the performance and design requirements to avoid static discharge for all electrostatic dissipative protective clothing as part of an entire earthed system, shoes, clothing & floor. The material meets the requirements.

![EN 13034 - What Is The Difference Between Type 6 And Type PB [6] Chemical Protection?](https://theppeonlineshop.co.uk/images/show_case/show_case_portwest_28_en_13034_88-1.jpg)

![EN 13034 - What Is The Difference Between Type 6 And Type PB [6] Chemical Protection?](https://theppeonlineshop.co.uk/images/show_case/show_case_portwest_28_en_13034_88-2.jpg)

EN 13034 specifies the performance requirements for disposable and re-usable limited performance chemical protective clothing (Type 6 and (Type PB [6]) garments. Limited performance chemical protective clothing (disposable and re-usable) is intended for use in cases of a potential exposure to a light spray, liquid aerosols, low volume splashes and in circumstances where a complete barrier to chemical exposure is not required.

The standard covers both chemical protective suits (Type 6) and partial body protection (Type PB [6])

Chemical Protective Suits (Type 6) cover and protect at least the trunk and the limbs, e.g. one piece coveralls or two piece suits with or without hood, boot-socks, or boot covers.

Partial Body Protection of similar limited performance Type PB [6] covers and protects only specific parts of the body, e.g. coats, aprons, sleeves, etc.

![EN 13034 - What Is The Difference Between Type 6 And Type PB [6] Chemical Protection Testing?](https://theppeonlineshop.co.uk/images/show_case/show_case_portwest_28_en_13034_89-1.jpg)

![EN 13034 - What Is The Difference Between Type 6 And Type PB [6] Chemical Protection Testing?](https://theppeonlineshop.co.uk/images/show_case/show_case_portwest_28_en_13034_89-2.jpg)

![EN 13034 - What Is The Difference Between Type 6 And Type PB [6] Chemical Protection Testing?](https://theppeonlineshop.co.uk/images/show_case/show_case_portwest_28_en_13034_89-3.jpg)

In order to ensure that a chemical protective suit meets Type 6 protection, it is tested using a mist or fine spray of water. The water is dosed with a mild detergent to produce a specified surface tension and injected with a dye to aid the assessment of leakage. The test subject wears an absorbent suit underneath the one to be tested, which absorbs any leaks and is stained by the dye. Success or failure is determined by measuring the total area of any stains on three suits and comparing this with the requirement. Leaks will typically occur at closures and interface areas, but the liquid can also seep through the material itself.

Type PB [6] testing is conducted in a similar way to the Type 6 suit test but only on partial body garments such as sleeves, aprons, coats, etc.

EN ISO 11612 is the standard for protective clothing which protects against heat and flame. Users for these garments include those who work in oil & gas, welding & allied processes, mining, petroleum and many other industries.

There are a host of specific tests conducted as part of EN ISO 11612, including tests for: Flame Spread, Tensile Strength, Tear Resistance, and Heat Resistance.

Flame Spread Test:

A flame is held against the fabric for ten seconds. After it is removed the fabric should not continue to burn. There should be no hole formation, melting or molten debris.

Tensile Strength Test:

The fabric must be able to withstand a minimum force of 300 newtons while being stretched or grabbed.

Tear Resistance Test:

The fabric must be able to withstand a minimum force of 10 newtons before it will tear.

Heat Resistance Test:

The fabric is placed in an oven at 180oC and must not ignite melt or shrink within the first 5 minutes in order to comply with the standard.

This standard investigates the fabric and garment's ability to protect against the thermal effects of an electric arc. This can be done via two test methods: 1. IEC 61482-1-1 (Open Arc Test Method) and 2. IEC 61482-1-2 (Box Test Method).

An electric arc is an intense flash of electricity which can result in numerous injuries.

Garments can be layered to achieve a better Cal rating. For example, a thermal layer may achieve an Ebt of 4.3 Cal/cm2, and an outer coverall may achieve an ATPV of 13.6 Cal/cm2. However, the combination ATPV/Ebt ratings will be greater than the sum of the two single layers, as the air gap between the two layers affords the wearer additional protection.

This test method aims to establish an ELIM (Incident Energy Limit) and an ATPV rating of a fabric and/or garment. These values, expresses as cal/cm², are the highest incident thermal energy to which the garment can be exposed without the wearer getting a second degree burn or the formation of holes in the fabric. The higher the cal rating of the garment or fabric, then the greater the protection for the wearer.

This test method aims to establish an APC1 or an APC2 rating of a fabric and/or garment (APC=Arc Protection Class). Test conditions for APC1 & APC2 try to simulate typical exposure conditions for a short circuit current of 4kA and 7kA respectively.

A single layer garment in most cases will pass APC1. For APC2, a thicker fabric or multi layer system is required.

Meet the Portwest Hi-Vis Modaflame Trousers in Yellow/Navy Short - your ultimate safety partner conforming to various EN standards to grant exceptional protection against industrial hazards. Engineered with precision and crafted for comfort, these trousers facilitate ease of movement while assuring a snug fit, thanks to the elasticated back waist.

Key Features:

Standards Compliance:

These trousers adhere to a stringent set of certifications underscoring its commitment to safety and quality, including:

Step into a realm of safety and comfort at your workplace with the Portwest Hi-Vis Modaflame Trousers in Yellow/Navy Short. These trousers encapsulate durability, functionality, and a high standard of protection, ready to stand firm in the face of industrial challenges.

Specifications are subject to change - See Terms & Conditions for more info

Portwest has been independently rated by Ecovadis for its environmental, social, and ethical performance and achieved a silver rating, meaning they are in the top 25% of globally rated companies.

The pillars taken into consideration include the environment, labour practices and human rights, ethics, and sustainable procurement.

This product conforms with essential health and safety requirements as set out in European Directives.

This symbol indicates UKCA marking in progress at time of print. All products placed on the UK market from January 2023 must be UKCA marked.

This product is CE marked as a Category 3 item for complex design.

40+ UPF rated fabric to block 98% of UV rays.

A mobile phone pocket is included in this garment.

This garment features 9 pockets.

This product has incorporated knee pad pockets that have been developed to carry Portwest's range of ergonomically designed knee pads.

Wash at a Maximum Temperature of 60°C using a normal wash cycle

Do not bleach this item

This item can be tumble dried on a normal temperature setting

This item can be ironed on a medium temperature setting of up to 150°C

Do not dry clean this item