EN 361 is the standard applied to Full Body Harnesses designed to hold the user in place and spread the load in the case of a fall arrest scenario (i.e. being brought to a stop following a period of free-fall).

Source: https://www.satra.com/ppe/EN361.php

This test aims to simulate the behaviour of the harness in a real- life scenario by subjecting it to a shock test for a load greater than what it would experience in use. Particular focus is given to the angle at which the user is held in the event of a fall. The harness is fitted with a 100kg solid torso dummy attached to a 2 metre length of 11mm mountaineering rope connected to a solid anchorage point and dropped in free fall for 4 metres. The test is carried out twice on each harness, once from a heads-up position, once from a heads-down position (i.e. with the dummy upside down on release). In order to pass the test the harness must hold the dummy after both drops in a position not exceeding 50 degrees from the upright position.

Strength tests known as tensile tests are used to gauge the breaking strength of whole products including harnesses and lanyards. Tensile forces are usually applied for at least 3 minutes to ensure that the breaking strength of the product is in excess of the force specified by the standard. These are based on a safety factor of 6kN, where KN equals Kilonewtons a measure of force.

The aim of this test is to prove that metallic components used in fall protection equipment can withstand a minimal resistance to environmental corrosion (specifically rust). In order to prove this, metal components are placed in a sealed chamber for 24 to 48 hours and subjected to salt water mist designed to induce rust in unprotected metals. They are then examined for rust and function afterwards.

Harnesses (or additional attachments on a full body harness) intended for use where free-fall is not used - in particular, work positioning/restraint and for use in abseiling or rope access.

(Please check the standards list below in the product details & specifications section to see which of these two standards applies to your product.)

As with full body harnesses, work positioning and sit / abseil harnesses are subjected to a drop test to generate a shock load on the harness. However, commensurate with the end use, a lesser force is applied to the harness as the possibility of a period of free-fall is significantly less in use. Work positioning attachments are subjected to a 1 metre drop with a 1 metre length of rope, whereas sit harnesses are dropped over a distance of 2 metres with a 1 metre length of rope. In both cases, the harness is required only to safely arrest the fall of the test dummy following the drop.

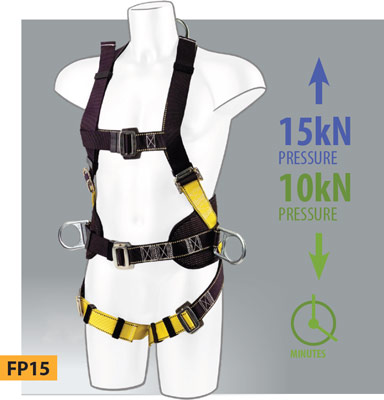

Whole products are subjected to tensile tests. Belts, harnesses and lanyards are subject to a 15kN tensile force. Tensile forces are applied and held for at least 3 minutes, to ensure the breaking strength of the product is in excess of the force specified by the standard.

Metallic components used in fall protection equipment are subjected to a neutral salt-spray test intended to prove a minimum resistance to environmental corrosion (specifically rust). Products are held within a sealed chamber, which is filled with a salt-water mist, which can induce rust in unprotected metals. Products are subjected to either 24 or 48 hours exposure and examined for rusting and function afterward.

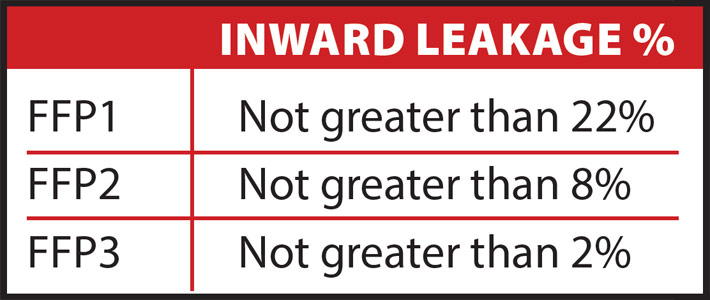

This test measures the probability of the respiratory mask to protect the wearer against potential hazards.

A test subject wearing the particle mask walks in an enclosed test room, with a constant concentration of sodium chloride aerosol. While the subject breathes, the air inside the mask is sampled and analysed to determine which % of sodium chloride could pass through the mask.

In the table to the left: The lower the percentage the higher the protection

Ensure your safety at height with the Portwest 3 Point Comfort Plus Harness in Red. This universal harness integrates all the essential features for fall arrest and protection in one comprehensive safety gear. With this harness, you gain not only security but also comfort thanks to its extra padding.

Key Features:

Certifications:

The Portwest 3 Point Comfort Plus Harness is your reliable partner for high elevation tasks, providing an unparallel safety solution, while ensuring comfort and freedom of movement. Make the smart choice for your safety with this well-rounded harness.

Specifications are subject to change - See Terms & Conditions for more info

Portwest has been independently rated by Ecovadis for its environmental, social, and ethical performance and achieved a silver rating, meaning they are in the top 25% of globally rated companies.

The pillars taken into consideration include the environment, labour practices and human rights, ethics, and sustainable procurement.

This product conforms with essential health and safety requirements as set out in European Directives.