For chemical protective clothing offering limited protective performance against liquid chemicals (Type 6 and Type PB [6] equipment). This standard specifies the minimum requirements for limited use and re-useable limited performance chemical protective clothing.

Limited performance chemical protective clothing is intended for use in cases of a potential exposure to a light spray, liquid aerosols or low pressure, low volume splashes, against which a complete liquid permeation barrier (at a molecular level) is not required.

Type 6 Chemical Protective suits must cover and protect at least the trunk and the limbs.

Example: One piece coveralls or two piece suits (with or without hood), boot-socks, or boot covers.

Type PB [6] Partial body protection covers and protects only specific parts of the body.

Example: coats, aprons, sleeves.

This European standard is part of a series of standards for test methods and requirements for electrostatic properties of protective clothing.

The standard specifies material and design requirements for garments used as part of a total earthed system, to avoid incendiary discharges.

The requirements may not be sufficient in oxygen enriched flammable atmospheres.

This European Standard is not applicable for specifying protection against main voltages.

Test method for measurement of surface resistivity. Surface resistance measures the conductivity between two points on the surface of a fabric. The lower the resistance the higher the conductivity, resulting in charge going to earth.

Test method for measurement of the electrical resistance through a material (vertical resistance). This is the level of conductivity when measured through the depth of a fabric.

Test methods for measurement of charge decay. Charge decay measures how long it takes for an electric current to dissipate. The quicker it dissipates the higher the anti-static properties of the garment.

Please note the EN 1149-4 Garment Test is under development.

EN 1149-5 specifies the performance and design requirements to avoid static discharge for all electrostatic dissipative protective clothing as part of an entire earthed system, shoes, clothing & floor. The material meets the requirements.

This standard specifies requirements and test methods for re-usable and limited use protective clothing providing protection against infective agents. Protective Clothing against infective agents; bacterial, viral and other micro-organisms has two main functions:

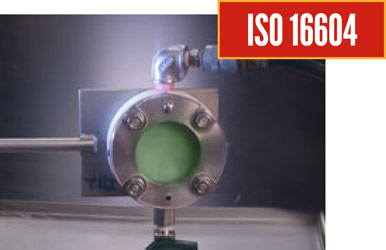

This test identifies the pressurisation at which the infected synthetic blood penetrates the material. The higher the class the greater the protection of the fabric.

| Class | 6 | 5 | 4 | 3 | 2 | 1 |

| Exposure pressure [kPa][log] | 20 | 14 | 7 | 3.5 | 1.75 | 0 |

This test uses a liquid (instead of synthetic blood) contaminated with a bacteriophage or virus in order to identify the pressurisation at which the liquid penetrates through the material.

| Class | 6 | 5 | 4 | 3 | 2 | 1 |

| Exposure pressure [kPa][log] | 20 | 14 | 7 | 3.5 | 1.75 | 0 |

This test superimposes a bacterial contaminated donor material on the test material and subjects it to mechanical rubbing. The results are recorded in accordance with breakthrough times ie: the point at which the bacteria penetrates the barrier material measured in minutes as highlighted in the table below. The longer the breakthrough time, the higher the class and therefore the greater the protection of the fabric.

| Class | 6 | 5 | 4 | 3 | 2 | 1 |

| Bacterial Penetration [min] | >75 | >60 | >45 | >30 | >15 | <15 |

This test is used to assess the barrier's effect against biologically contaminated aerosols. A bacterium solution is suspended in an aerosol and sprayed on to both an unprotected cellulose nitrate membrane, and one covered with the test material. Both membranes are analysed to establish the bacterial load and the results are classified by the penetration ratio. The higher the class the greater the protection of the fabric.

| Class | 3 | 2 | 1 |

| Penetration ratio without/with test material [log] | >5 | >2 | >1 |

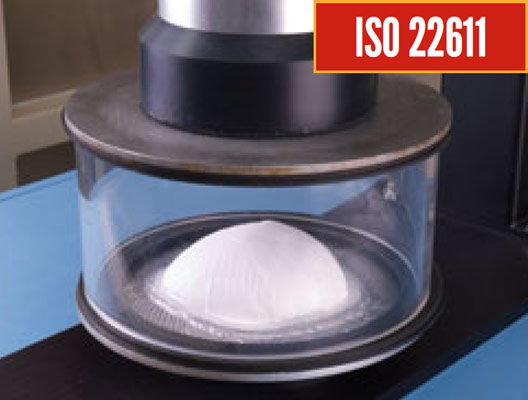

A pre sterilised material is fixed in a testing apparatus and administrated with contaminated talcum power (Bacillus Subtilis). An agar plate is placed underneath the material while it is be shaken. The particles, which penetrate the material, are analysed after incubation of the agar plate and the results are measured in penetration log units as highlighted in the table below: The higher the class the greater the protection of the fabric.

| Class | 3 | 2 | 1 |

| Penetration ratio without/with test material [log] | ≤ 1 | ≤ 2 | ≤ 3 |

![EN 13034 - What Is The Difference Between Type 6 And Type PB [6] Chemical Protection?](https://theppeonlineshop.co.uk/images/show_case/show_case_portwest_28_en_13034_88-1.jpg)

![EN 13034 - What Is The Difference Between Type 6 And Type PB [6] Chemical Protection?](https://theppeonlineshop.co.uk/images/show_case/show_case_portwest_28_en_13034_88-2.jpg)

EN 13034 specifies the performance requirements for disposable and re-usable limited performance chemical protective clothing (Type 6 and (Type PB [6]) garments. Limited performance chemical protective clothing (disposable and re-usable) is intended for use in cases of a potential exposure to a light spray, liquid aerosols, low volume splashes and in circumstances where a complete barrier to chemical exposure is not required.

The standard covers both chemical protective suits (Type 6) and partial body protection (Type PB [6])

Chemical Protective Suits (Type 6) cover and protect at least the trunk and the limbs, e.g. one piece coveralls or two piece suits with or without hood, boot-socks, or boot covers.

Partial Body Protection of similar limited performance Type PB [6] covers and protects only specific parts of the body, e.g. coats, aprons, sleeves, etc.

![EN 13034 - What Is The Difference Between Type 6 And Type PB [6] Chemical Protection Testing?](https://theppeonlineshop.co.uk/images/show_case/show_case_portwest_28_en_13034_89-1.jpg)

![EN 13034 - What Is The Difference Between Type 6 And Type PB [6] Chemical Protection Testing?](https://theppeonlineshop.co.uk/images/show_case/show_case_portwest_28_en_13034_89-2.jpg)

![EN 13034 - What Is The Difference Between Type 6 And Type PB [6] Chemical Protection Testing?](https://theppeonlineshop.co.uk/images/show_case/show_case_portwest_28_en_13034_89-3.jpg)

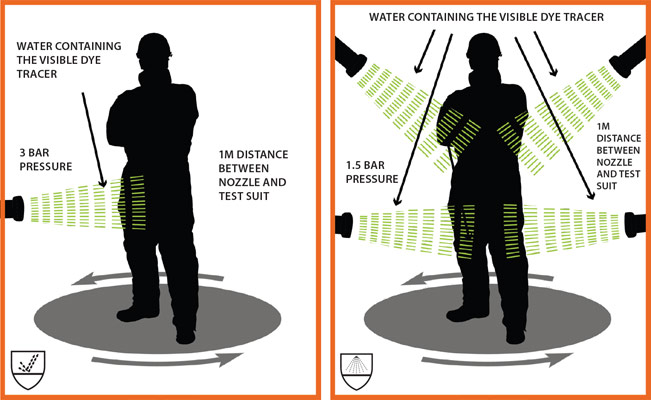

In order to ensure that a chemical protective suit meets Type 6 protection, it is tested using a mist or fine spray of water. The water is dosed with a mild detergent to produce a specified surface tension and injected with a dye to aid the assessment of leakage. The test subject wears an absorbent suit underneath the one to be tested, which absorbs any leaks and is stained by the dye. Success or failure is determined by measuring the total area of any stains on three suits and comparing this with the requirement. Leaks will typically occur at closures and interface areas, but the liquid can also seep through the material itself.

Type PB [6] testing is conducted in a similar way to the Type 6 suit test but only on partial body garments such as sleeves, aprons, coats, etc.

This standard specifies performance requirements for clothing with liquid-tight (Type 3) or spray-tight (Type 4) connections, including items providing protection to parts of the body only. (Types PB [3] and PB [4])

Pass or Fail Criteria for EN 14605 - If any penetration is greater than 3 times the total calibration stain area. The tests below are repeated on 3 suits and all 3 must pass.

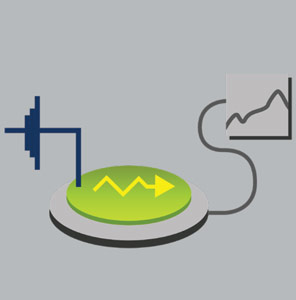

Suits which protect against strong jets of liquid chemicals. This test involves exposing a whole suit on a rotating platform to a series of short jets of a water based liquid containing a fluorescent or visible dye tracer, aimed at various critical parts of the suit.

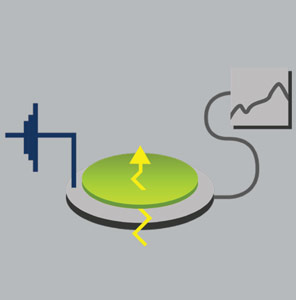

Suits which protect against saturation of liquid chemicals. This test involves exposing a whole suit on a rotating platform to an intense spray of a water based liquids, containing fluorescent or visible dye tracer, aimed at various critical parts of the suit.

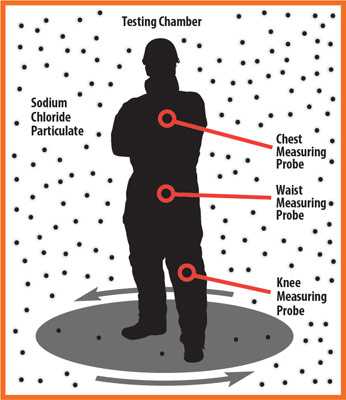

This standard specifies the requirements and test methods for non-ventilated protective clothing against particulate radioactive contamination. The standard tests for inward leakage of aerosols & fine particles as tested in EN ISO 13982-1.

Nominal Protection Factor & Performance Class for suit particle protection level: (see table to the left)

A suit which offers the highest protection to the fine particulates will have low inward leakage, and thus a high nominal protection factor.

A person wearing the protective suit enters a "testing chamber". Beneath the protective suit, the person has three measuring probes attached (one on the chest, one at the waist and one at the knee). Sodium chloride particulates (average size of 0.6 microns) are distributed throughout the cabin, the wearer performs a series of three physical activities:

» 3 minutes standing still

» 3 minutes "on the spot" walking (5km/h)

» 3 minutes squatting (at a rate of 5 squats per minute)

Sodium chloride particulates that penetrate the protective suit are counted by the probes beneath the suit. The results are used to determine both a performance classification and a "nominal protection factor".

Introducing the Portwest BizTex Microporous Coverall Type 3/4/5/6 - Yellow: a pinnacle of protection in the realm of coveralls. Crafted to offer unparalleled mechanical strength combined with protection against liquids and particulates, this coverall ensures safety even in the most demanding situations.

Key Features:

Complying with an extensive range of standards, including Centro Tessile Cotoniero e Abbigliamento S.p.A, EN 14605 Type 3B, EN 14605 Type 4B, EN ISO 13982 Type 5B, EN 13034 Type 6B, EN 1073-2, EN 1149 -5, and EN 14126, this coverall sets the benchmark for safety in challenging environments.

Choose the Portwest BizTex Microporous Coverall Type 3/4/5/6 - Yellow for an embodiment of safety and functionality. Made for professionals who seek optimal protection without compromising on comfort.

Introducing the Portwest BizTex Microporous Coverall Type 3/4/5/6 - Yellow: a pinnacle of protection in the realm of coveralls. Crafted to offer unparalleled mechanical strength combined with protection against liquids and particulates, this coverall ensures safety even in the most demanding situations.

Key Features:

Complying with an extensive range of standards, including Centro Tessile Cotoniero e Abbigliamento S.p.A, EN 14605 Type 3B, EN 14605 Type 4B, EN ISO 13982 Type 5B, EN 13034 Type 6B, EN 1073-2, EN 1149 -5, and EN 14126, this coverall sets the benchmark for safety in challenging environments.

Choose the Portwest BizTex Microporous Coverall Type 3/4/5/6 - Yellow for an embodiment of safety and functionality. Made for professionals who seek optimal protection without compromising on comfort.

Introducing the Portwest BizTex Microporous Coverall Type 3/4/5/6 - Yellow: a pinnacle of protection in the realm of coveralls. Crafted to offer unparalleled mechanical strength combined with protection against liquids and particulates, this coverall ensures safety even in the most demanding situations.

Key Features:

Complying with an extensive range of standards, including Centro Tessile Cotoniero e Abbigliamento S.p.A, EN 14605 Type 3B, EN 14605 Type 4B, EN ISO 13982 Type 5B, EN 13034 Type 6B, EN 1073-2, EN 1149 -5, and EN 14126, this coverall sets the benchmark for safety in challenging environments.

Choose the Portwest BizTex Microporous Coverall Type 3/4/5/6 - Yellow for an embodiment of safety and functionality. Made for professionals who seek optimal protection without compromising on comfort.

Introducing the Portwest BizTex Microporous Coverall Type 3/4/5/6 - Yellow: a pinnacle of protection in the realm of coveralls. Crafted to offer unparalleled mechanical strength combined with protection against liquids and particulates, this coverall ensures safety even in the most demanding situations.

Key Features:

Complying with an extensive range of standards, including Centro Tessile Cotoniero e Abbigliamento S.p.A, EN 14605 Type 3B, EN 14605 Type 4B, EN ISO 13982 Type 5B, EN 13034 Type 6B, EN 1073-2, EN 1149 -5, and EN 14126, this coverall sets the benchmark for safety in challenging environments.

Choose the Portwest BizTex Microporous Coverall Type 3/4/5/6 - Yellow for an embodiment of safety and functionality. Made for professionals who seek optimal protection without compromising on comfort.

Introducing the Portwest BizTex Microporous Coverall Type 3/4/5/6 - Yellow: a pinnacle of protection in the realm of coveralls. Crafted to offer unparalleled mechanical strength combined with protection against liquids and particulates, this coverall ensures safety even in the most demanding situations.

Key Features:

Complying with an extensive range of standards, including Centro Tessile Cotoniero e Abbigliamento S.p.A, EN 14605 Type 3B, EN 14605 Type 4B, EN ISO 13982 Type 5B, EN 13034 Type 6B, EN 1073-2, EN 1149 -5, and EN 14126, this coverall sets the benchmark for safety in challenging environments.

Choose the Portwest BizTex Microporous Coverall Type 3/4/5/6 - Yellow for an embodiment of safety and functionality. Made for professionals who seek optimal protection without compromising on comfort.

Specifications are subject to change - See Terms & Conditions for more info

Portwest has been independently rated by Ecovadis for its environmental, social, and ethical performance and achieved a silver rating, meaning they are in the top 25% of globally rated companies.

The pillars taken into consideration include the environment, labour practices and human rights, ethics, and sustainable procurement.

This product conforms with essential health and safety requirements as set out in European Directives.

This product is CE marked as a Category 3 item for complex design.

This garment has taped waterproof seams.

This garment comes with a non-detachable hood.

Do not wash this item

Do not bleach this item

This item must not be tumbled dried

Do not iron this item

Do not dry clean this item